Cleaning & Disinfection of Water Pipes, Tanks, Reservoirs, and Filters

Disinfection and Maintenance of Potable and Non-Potable Water Systems

Disinfection and Maintenance of Potable and Non-Potable Water Systems

The growth of microorganisms such as bacteria, yeasts, and fungi in water treatment, storage, and transport installations is problematic. At best, microorganisms and biofilms increase corrosion. At worst, they pose a threat to human health and the environment.

Microorganism development in water systems usually starts even before the installation of pipes, tanks, filters, and fittings – and certainly with their commissioning. All water-carrying constructions, where water remains stagnant for any period, are particularly vulnerable. Therefore, the need for regular cleaning and subsequent disinfection of such systems is undeniable. However, this requires expertise in the appropriate procedures and suitable products.

Sanosil disinfection products, featuring stabilized and catalytically boosted hydrogen peroxide, are undoubtedly among the best in their class for the above-mentioned applications. Thus, it is a wise decision to consistently rely on Sanosil for disinfection tasks in the water sector.

Highly concentrated disinfectant for water and water systems

Disinfectant (non-hazardous) for water and water systems

Broad-spectrum descaling agent & corrosion protection for cleaning and descaling tanks, pipes and technical systems

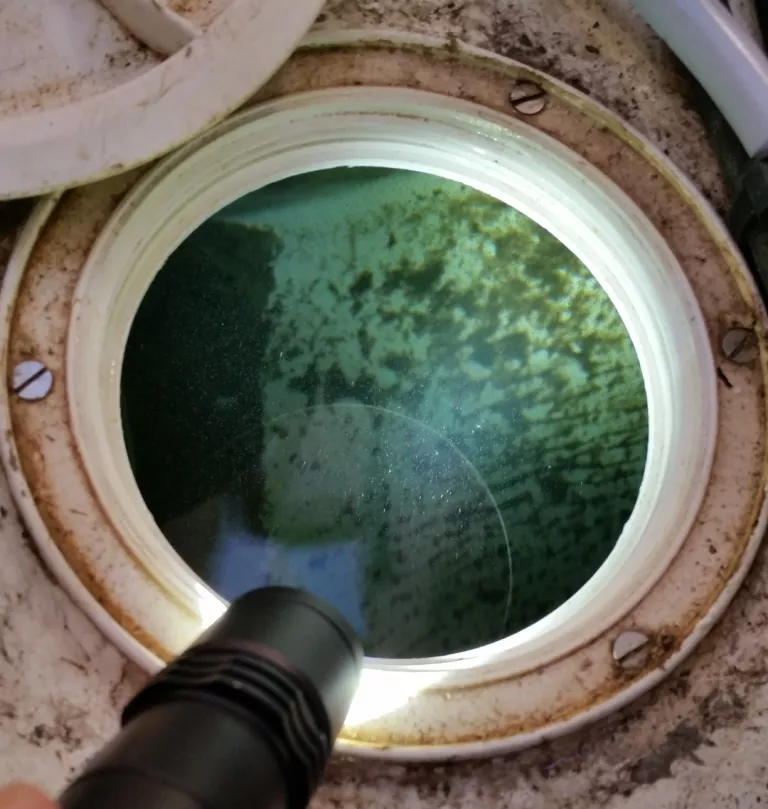

Biofilms are complex communities of microorganisms that adhere to surfaces and are surrounded by a slimy layer. They tend to form rapidly in water-carrying systems because these environments provide favorable conditions for microbial growth. An important cause of biofilm growth in water-carrying systems is the presence of nutrients. These nutrients can come from various sources, such as the water supply itself, contaminants from the environment, or deposits within the system. Microorganisms utilize these nutrients to grow and multiply.

Another crucial factor is the surface characteristics of pipes and conduits. Many water-carrying systems have deposits and rough areas that serve as ideal breeding grounds for microorganisms. Once a germ has settled in such a spot, a biofilm forms rapidly around it.

Additionally, other factors such as temperature, pH, water quality, and flow rate can influence the growth of biofilms and germs. Therefore, it is essential to regularly clean and disinfect water-carrying systems to reduce biofilm and germ growth and maintain water quality.

Water tanks need to be cleaned and disinfected regularly to prevent the growth of bacteria, algae, fungi, and other microorganisms and to maintain water quality. There are several reasons why this is necessary:

Regular cleaning and disinfection keep the water in a hygienic state, extend the lifespan of the water tank, and reduce maintenance costs.

The frequency of cleaning and disinfection depends on various factors, such as the size of the tank, the type of water, frequency of use, and environmental conditions. Typically, experts recommend an annual cleaning and disinfection of water tanks to ensure optimal water quality.

There are various types of water filters designed for different purposes and applications. Here are some common types of water filters:

These filters have one thing in common: they all have a large surface area – and as they filter water, filter sludge accumulates in them. This sludge is often nutrient-rich, making it an excellent substrate for microbial colonization. Additionally, many filters are only intermittently supplied with water – during periods of stagnation, germs can multiply significantly. Regular cleaning and disinfection free the filters from sediments and germs, increase flow performance, and optimize water quality.

While many products have varying degrees of effectiveness against waterborne germs, some quickly reach their limits once biofilms begin to grow within a system. For instance, commonly used chlorine bleach (hypochlorite) is largely ineffective against the surfaces of biofilms.

Sanosil disinfectant products, with stabilized and catalytically enhanced hydrogen peroxide, however, can penetrate deep into biofilm structures, dislodging them and combating the released germs.

After disinfection, the boosted hydrogen peroxide practically decomposes to 100% into water and oxygen.

In many water systems, especially in the drinking water sector, some products are unpopular due to changes in the water’s odor and taste. This is often a common objection, particularly in emergency water preservation.

Sanosil disinfectants, on the other hand, are odorless and tasteless – and they also have a significantly longer shelf life in water preservation compared to chlorine or chlorine dioxide.

Our core competencies include the manufacturing and application consulting of disinfection products for water systems, surfaces, and air (complete room disinfection).