Disinfection of a Contaminated Animal Drinking Trough in Poultry Farming

Drinking facilities in poultry farming have long pipelines. Especially during the introduction of new batches, when fresh chicks are placed for fattening, very little drinking water is consumed. Coupled with high temperatures in the poultry house, germs multiply rapidly in the drinking water. This situation worsens if old biofilms and deposits from vitamins or medications adhere to the pipelines.

Thorough cleaning and disinfection remove these contaminants and significantly reduce infection pressure on the poultry.

- Subject: Drinking trough facilities in a poultry farming operation

- Product used: Sanosil Super 25

- Method: Shock disinfection / maintenance treatment

Scenario description

A poultry farming operation is experiencing high bacterial counts in its water: approximately 11,000 aerobic mesophilic organisms and E. coli per milliliter. (For comparison, the maximum acceptable level for drinking water is 100 CFU/ML.) Additionally, sporadic visible flushes („flecks“) of biofilms are observed.

Specifics

The mortality rate among chicks due to diarrhea is unacceptably high.

Execution

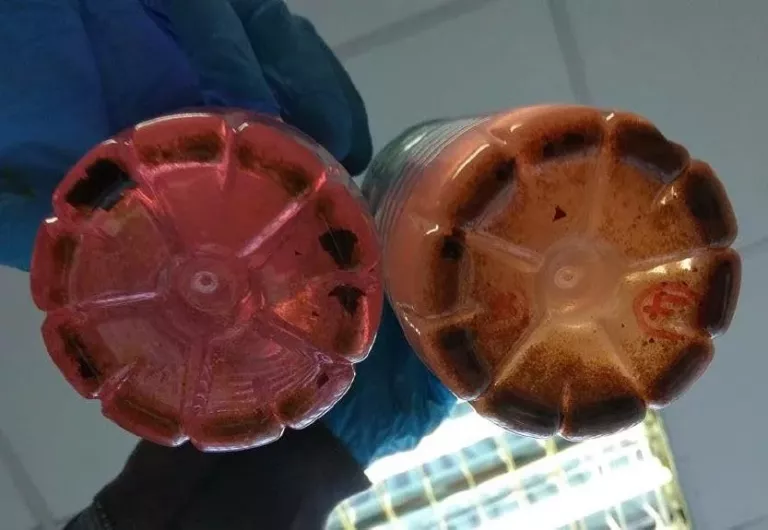

The storage and medication tank is manually dosed with 1 liter of Sanosil Super 25 per cubic meter. Simultaneously, a small amount of red food coloring is added to visualize the distribution of the disinfectant solution within the system. Subsequently, the solution is pumped through the drinking water system until the entire system is completely flooded with the Sanosil solution.

After approximately 3 hours, a noticeable detachment of biofilms in the pipelines is observed. The following day, the entire water system is thoroughly flushed until all detached deposits are removed. During the fattening period, a small amount of Sanosil (approximately 30 ppm = 30 ml/m³ of water) is continuously added to the drinking water. Approximately 20 ppm can still be detected in the furthest part of the drinking system setup.

Results

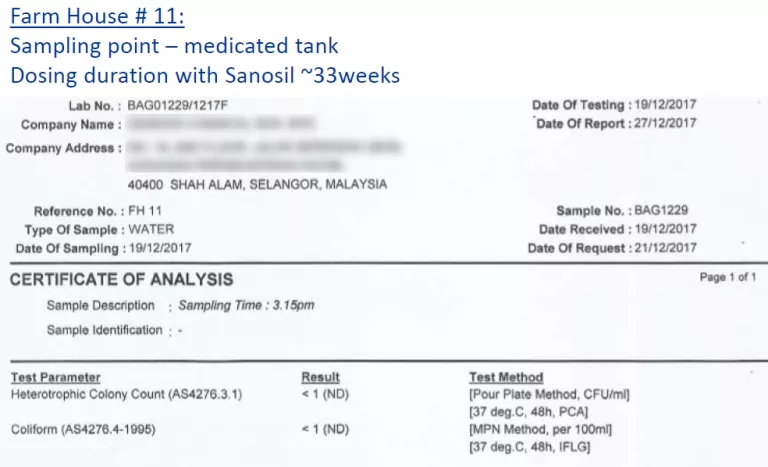

Laboratory analysis of a water sample reveals the absence of aerobic mesophilic and coliform bacteria. Subsequently, the entire poultry farming operation switches to using Sanosil Super 25 for water hygiene. After 33 weeks, another water sample is taken, confirming no bacterial growth. The pipelines are visually clean and free from biofilms.

Since 2017, this approach has proven effective, significantly reducing chick mortality due to diarrhea. Compared to previous methods like chlorine, there is noticeably less irritation to the animals‘ eyes and respiratory systems. The animals consume more water, contributing to optimal feed conversion and quicker attainment of slaughter weight.

Relevant Brochures for This Application

Core Competencies

Our core competencies include the manufacturing and application consulting of disinfection products for water systems, surfaces, and air (complete room disinfection).

0 COMMENT(S) ON THIS ARTICLE

Please note that your sent comments must first be approved by our moderation team before they become visible.