Disinfection of Cell Culture Wash Water / Laboratory Wastewater

A laboratory opts to replace its previously used aldehyde and QAC product for the inactivation of various liquid wastes with a more environmentally friendly product. The method and product need to be internally evaluated and validated for this purpose.

- What is being treated? – Cell culture wash water

- With which product? – Sanosil S015

- Method of application: Shock disinfection

General

The entire procedure is conducted under a safety cabinet in sterile conditions to prevent air contamination of the inoculated agar plates.

Procedure

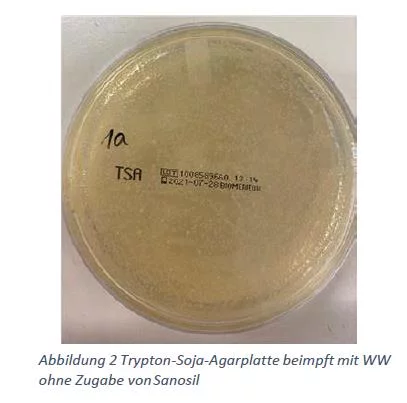

Collection of wastewater: Wash water from a BioTek plate washer containing various serum and blood samples, HRP’s, Tween, acids, and various other interfering substances. Exact concentrations cannot be defined; pH ranges from approximately 6.5 to 7.5. It is collected over 2 days in a 10L container and left closed at room temperature during this time.

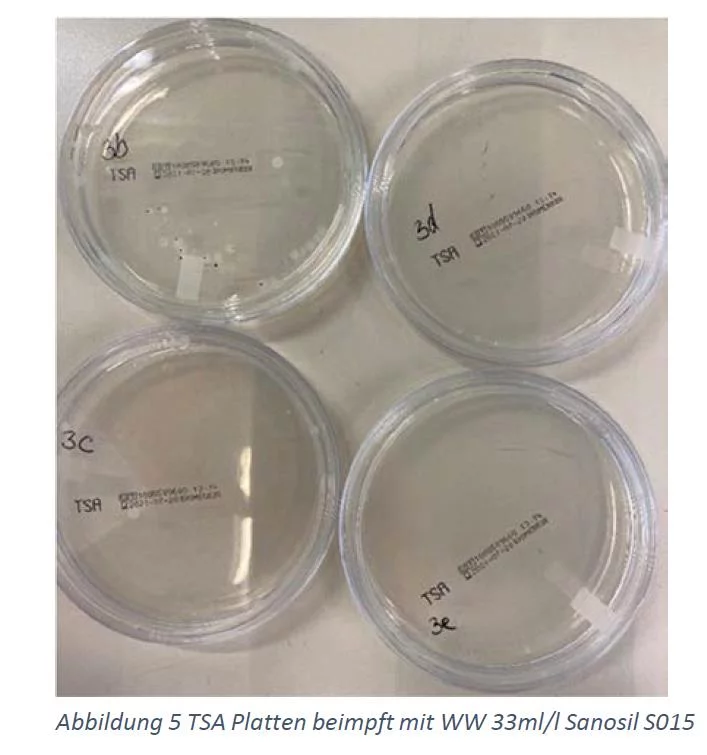

5 wastewater samples were aliquoted and different volumes of Sanosil S015 were added to each aliquot. Samples were then taken from each wastewater aliquot at defined intervals and streaked onto two types of agar plates. Both TSA plates and SDA plates were incubated at their respective optimal temperatures, and after 3/5 days, colony-forming units (CFUs) were counted. This was done to determine the specific impact of Sanosil S015 on bacterial/fungal growth.

Laboratory Result

In Switzerland, the general guideline for water discharged into the distribution network is not to exceed 300 CFU/ml.

With an addition of 6.6 ml/l of Sanosil S015 and an exposure time of 45 minutes, the value is reduced to 230 CFU/ml, which is already below the critical threshold.

Conclusion / Result

The customer decides to apply a high safety margin and prescribe a dosage of 33 ml/l with an exposure time of 60 minutes. With this approach, 0 CFU/ml are counted in all samples.

The procedure and dosage will be documented accordingly in the internal quality management (QM) system.

Relevant Brochure For This Application

Core Competencies

Our core competencies include the manufacturing and application consulting of disinfection products for water systems, surfaces, and air (complete room disinfection).

0 COMMENT(S) ON THIS ARTICLE

Please note that your sent comments must first be approved by our moderation team before they become visible.