Application of Sanosil Disinfectant in a Greenhouse Irrigation System

Biofilms can quickly form in irrigation systems. At best, these can clog hoses, pipes, and nozzles; at worst, they can spread plant diseases, especially in recirculation systems. Regular disinfection of the irrigation system effectively prevents these problems.

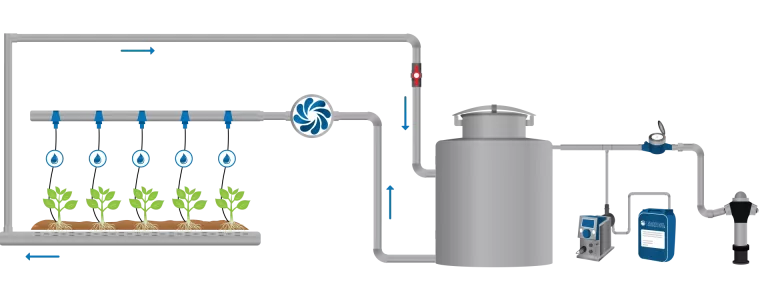

- What is treated? Top feeder/dripper irrigation system

- With which product? Sanosil Super 25

- Application type: Alternating shock and maintenance disinfection

Situation description

A large plant cultivation operation with greenhouses and the use of district heating. Tomatoes and cucumbers are grown for 8-9 months at a stretch, followed by some lettuce and about 1 month of fallow for cleaning, maintenance, and re-setup.

Irrigation technology used: Central system with drip feeders (spaghetti tubes) and water recycling.

Issues / special considerations

Standing water overnight in the irrigation system promotes the growth of agrobacteria (Agrobacterium rhizogenes). Agrobacteria are responsible for „Crazy Roots,“ a feared plant disease. Pythium or Fusarium fungal infections also occur but are less common.

Execution

Shock disinfection of the entire system, including the return flow, with 1 liter/m³ of Sanosil Super 25 during maintenance/fallow periods. At the start of the irrigation cycle, continuous addition of 10 ml/m³ of Sanosil Super 25 directly into the nutrient solution is implemented.

Since no further shock disinfection is conducted for the entire 8-9 month season, the required dosage gradually increases to about 20 ml/m³ over time. The maintenance disinfection with these low dosages significantly inhibits biofilm formation in the system, although it may not always completely prevent it. Consequently, the amount of organic material in the pipes increases, causing an accelerated breakdown of hydrogen peroxide.

The increasing degradation rate of the disinfectant in the water and pipes is therefore compensated by a slow increase in dosage.

Result

This approach has proven to be very effective over the years. Since its implementation, there have been no issues with Agrobacterium rhizogenes, Pythium, Fusarium, or system blockages due to biofilms. The client plans to continue this treatment method in the future.

Relevant Brochures for This Application

Core Competencies

Our core competencies include the manufacturing and application consulting of disinfection products for water systems, surfaces, and air (complete room disinfection).

0 COMMENT(S) ON THIS ARTICLE

Please note that your sent comments must first be approved by our moderation team before they become visible.