Disinfection of Drinking Systems and Drinking Water in Animal Farming

Control of microorganisms in water systems of animal housing

Control of microorganisms in water systems of animal housing

Good water hygiene is essential in poultry farming to optimize and complete the hygiene concept. Chickens and other poultry require a constant supply of clean drinking water to stay healthy and grow optimally. If the drinking system or water is contaminated with microorganisms, it can lead to diseases, poor growth, and low productivity. Moreover, poor water hygiene can also promote the spread of diseases among the animals. Therefore, water hygiene is a crucial aspect of poultry farming and should be taken seriously.

Sanosil disinfectants are often significantly better suited for this purpose than other products due to their formula with catalytically enhanced hydrogen peroxide, impressive efficacy, and good material compatibility.

Highly concentrated disinfectant for water and water systems

Broad-spectrum descaling agent & corrosion protection for cleaning and descaling tanks, pipes and technical systems

High-quality drinking water is crucial for the upbringing and maintenance of animals. While water often starts with acceptable quality from public water networks or farm-owned sources, it becomes susceptible to the risk of acute contamination once it enters the distribution system for drinking water.

Therefore, regular cleaning and disinfection of drinking troughs, and when necessary, water treatment, are of utmost importance.

In poultry houses, water pipes and drinkers are prone to rapid formation of microorganisms and biofilms due to several contributing factors. One critical factor is the warm and humid environment typical of poultry houses, which creates ideal conditions for microbial growth.

Additionally, the type of water used in drinkers can also influence microbial growth. Water sourced from mineral-rich springs, for example, may lead to mineral deposits that provide surfaces where microorganisms can thrive, facilitating the formation of biofilms.

Furthermore, contaminants such as feed residues or feces can promote microbial growth. These deposits make it challenging to effectively use suitable disinfectants for water sanitation in poultry houses, as the high organic content neutralizes a portion of the hygiene products applied.

Tiertränken in Geflügelställen können sich leicht mit Rückständen aus fettlöslichen Vitaminen und Medikamenten verstopfen. Dies liegt daran, dass diese Substanzen in der Regel nicht wasserlöslich sind und sich daher nicht gut mit dem Wasser vermischen.

Wenn sie in das Tränkesystem gegeben werden, können sie sich an den Innenwänden der Tränken oder der Wasserleitung ablagern und im Laufe der Zeit einen Biofilm bilden. Dieser Biofilm kann wiederum dazu beitragen, dass sich weitere Rückstände ablagern und die Wasserleitung verstopfen.

Ein weiterer Faktor, der zur Bildung von Rückständen beitragen kann, ist die Dosierung von Medikamenten oder fettlöslichen Vitaminen. Wenn die Dosierung nicht genau stimmt, kann es zu einer Ansammlung von ungenutzten oder überschüssigen Substanzen im Wasser kommen.

Um die Bildung von Rückständen in Tränkesystemen zu reduzieren, sollten diese regelmäßig gereinigt und desinfiziert werden. Es ist auch wichtig, die Dosierung von Medikamenten und fettlöslichen Vitaminen genau zu überwachen und sicherzustellen, dass nur die benötigte Menge verwendet wird. Wenn möglich, sollten wasserlösliche Formen von Vitaminen und Medikamenten verwendet werden, um die Bildung von Rückständen in den Tränken zu minimieren.

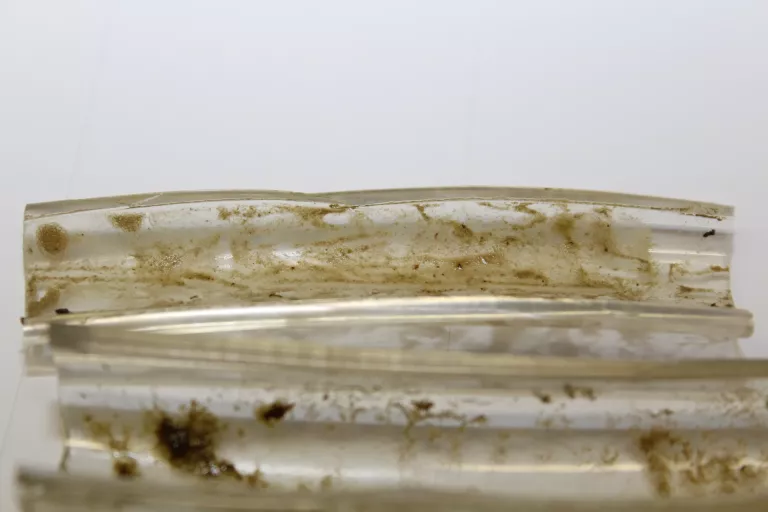

In poultry houses, drinkers can easily become clogged with residues from fat-soluble vitamins and medications. This occurs because these substances are typically not water-soluble and therefore do not mix well with water. When introduced into the drinking system, they can deposit on the inner walls of drinkers or water pipes over time, forming a biofilm. This biofilm, in turn, can contribute to further deposits and clogging of the water pipes.

Another factor contributing to residue formation is the dosage of medications or fat-soluble vitamins. Incorrect dosages can lead to the accumulation of unused or excess substances in the water.

To reduce the formation of residues in drinker systems, regular cleaning and disinfection are essential. It is also crucial to monitor the dosage of medications and fat-soluble vitamins carefully to ensure only the required amount is used. Whenever possible, water-soluble forms of vitamins and medications should be utilized to minimize residue formation in drinkers.

Simply disinfecting water is not a significant challenge for a water disinfectant. However, once biofilms are present in a system, this significantly complicates the effectiveness of treatment. Many products, like the commonly used chlorine, lose their efficacy on the surfaces of biofilms.

Sanosil disinfectant products, with stabilized and enhanced hydrogen peroxide, can penetrate deep into biofilm structures, detach them, and combat the released microbes. After disinfection, hydrogen peroxide breaks down completely into water and oxygen within a reasonable time frame.

Another critical aspect is their application in treating drinking water for animal and poultry farming (where legally approved). While chlorinating drinking water for animals enhances water hygiene, it can also lead to eye irritation in animals due to trihalomethanes. Chlorinated drinking water is generally not favored by animals, which can slow down their growth to slaughter weight.

Sanosil disinfectants, when continuously added in low doses to water, do not cause any odor or taste changes and are willingly accepted by animals in this role.

Thanks to the multifunctional application capabilities of Sanosil disinfectants, their use is naturally not limited to just water and water systems.

These products are also ideal for disinfecting cleaned surfaces in animal barns. Unlike aldehyde-based products, which often require waiting for days before animals can be reintroduced, surface disinfection with Sanosil does not necessitate extra waiting times.

Our core competencies include the manufacturing and application consulting of disinfection products for water systems, surfaces, and air (complete room disinfection).