Drinking Water Disinfection

Treatment and conservation of drinking water

Treatment and conservation of drinking water

The treatment of drinking water and/or emergency water preservation using hydrogen peroxide-containing products like Sanosil requires specific approvals, which may not be available in all countries. Please verify the use of these products with the appropriate authorities if uncertain.

Regardless of country-specific approvals for drinking water treatment, Sanosil products can be used for process water treatment, intermittent disinfection of drinking water systems such as tanks, pipelines, filters, etc., and intermittent Legionella control.

Highly concentrated disinfectant for water and water systems

Disinfectant (non-hazardous) for water and water systems

Disinfectant / preservative for drinking and emergency water

Mechanical methods for drinking water purification are among the oldest and simplest methods of water treatment. For instance, gravel and sand filters have been used since the Middle Ages to clean rainwater before storing it in cisterns. Water treatment through filtration also includes the use of fabric filters, ceramic filters, and membrane filters such as micro- and reverse osmosis filters. In water treatment plants, materials like sand, diatomaceous earth, and activated carbon are used as filter media.

Particle filters are effective in removing impurities such as sand, algae, and dirt from raw water. Additionally, membrane filters have the capability to separate microorganisms and even dissolved substances like salts.

To enhance the efficiency of filters, flocculants are often added. These substances cause small dirt particles to clump together into larger flocs, which can then be more effectively trapped in the filter mesh. To prevent clogging that could hinder filter performance, filters need to be regularly backwashed. During this process, accumulated suspended solids are flushed out against the normal flow direction and removed. However, backwashing membrane filters such as microfilters, nanofilters, or reverse osmosis filters is difficult to impossible. Therefore, membrane filters require regular cleaning and disinfection with suitable products to prevent fouling.

Not all undesired substances can be removed from drinking water solely through conventional filtration methods. Particularly, dissolved substances require other methods for removal. Many of these, such as iron and manganese, can be eliminated through oxidation. This process involves adding oxygen, air, hydrogen peroxide, or potassium permanganate.

Additionally, certain substances can be converted into a gaseous form and „stripped“ or removed from water by aerating the water with air. This includes excess chlorine, hydrocarbons, and sulfur compounds. This method improves taste and odor in drinking water treatment and is referred to as „stripping.“

A combination of chemical and mechanical water treatment is achieved through the use of absorbents. Water filters with activated carbon have proven effective in this regard. Due to its large surface area and reactivity, activated carbon can adsorb many substances, thereby further filtering unwanted elements from water.

In addition to filtration, biocidal techniques are employed for disinfecting drinking water. Common methods include UV disinfection, ozonation, chlorine dioxide, chlorination, or specific drinking water disinfectants like Sanosil Super 25. It’s crucial that all relevant germs are effectively and reliably killed while ensuring there are no negative changes in taste. Thermal disinfection (boiling water) is impractical in drinking water treatment due to high energy consumption and is typically only feasible outdoors or as an emergency measure in households for sudden contamination incidents.

To ensure the treated drinking water remains safe and protected from recontamination, a process known as pipeline protection is applied. Ozone or UV rays have localized effects and do not provide continuous protection. Therefore, a small amount of disinfectant is added to the drinking water to safeguard it against recontamination after treatment.

Water treatment to achieve drinking water quality is typically organized at the municipal level. However, there are consumers who undertake private water treatment, often on properties with their own wells, springs, or rainwater cisterns.

For water used solely for household purposes like gardening, showering, washing, and toilet flushing, and if the water in the cistern undergoes regular turnover, a simple filtration system with two sequentially connected backwashable filter cartridges is generally sufficient. Periodic tank cleaning is also advisable.

For drinking water treatment:

If the goal is to produce drinking water using a private system, more effort is required. The simplest approach involves a multi-stage household water treatment system. These systems typically consist of modules in sequence, combining pre-filters, ceramic filters, activated carbon filters, and UV disinfection or pre-filters/microfilters. When properly installed and maintained, these systems can effectively produce safe drinking water from private sources at home.

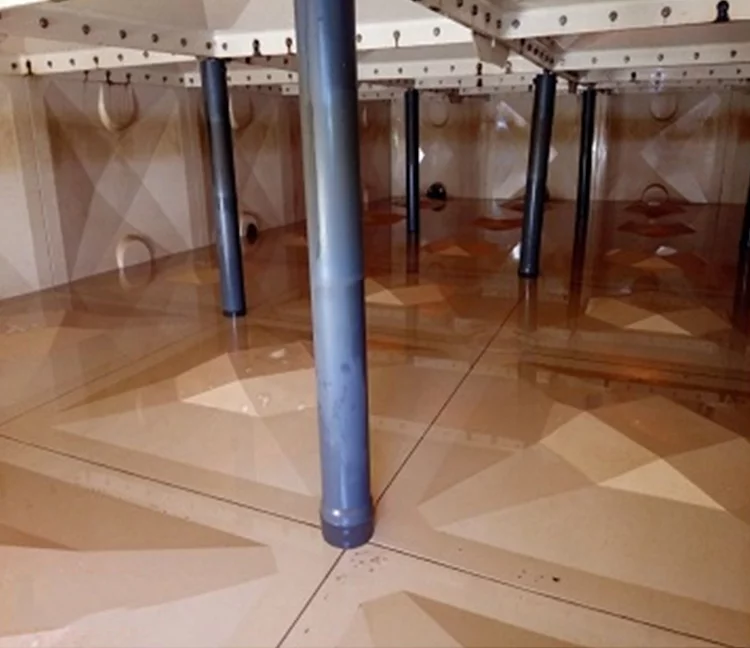

Generally, chemical disinfection of drinking water is not necessary for actual water treatment. However, regular monitoring and cleaning/disinfection of water storage and distribution systems, including filter disinfection, are essential. Sanosil products (S015 / Super 25) are excellent for disinfecting tanks, filters, and pipelines in such applications.

Our core competencies include the manufacturing and application consulting of disinfection products for water systems, surfaces, and air (complete room disinfection).